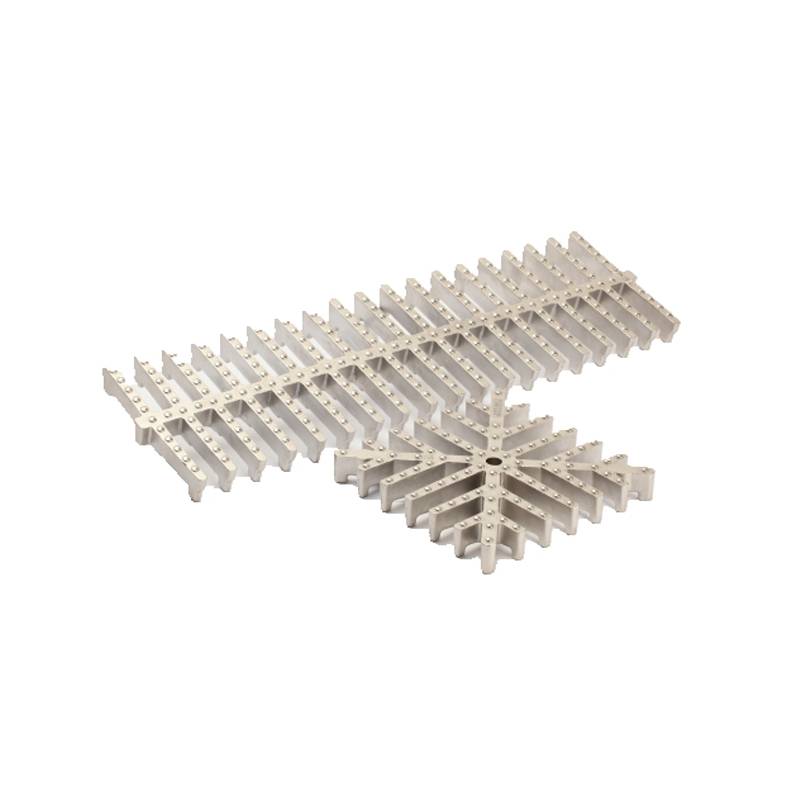

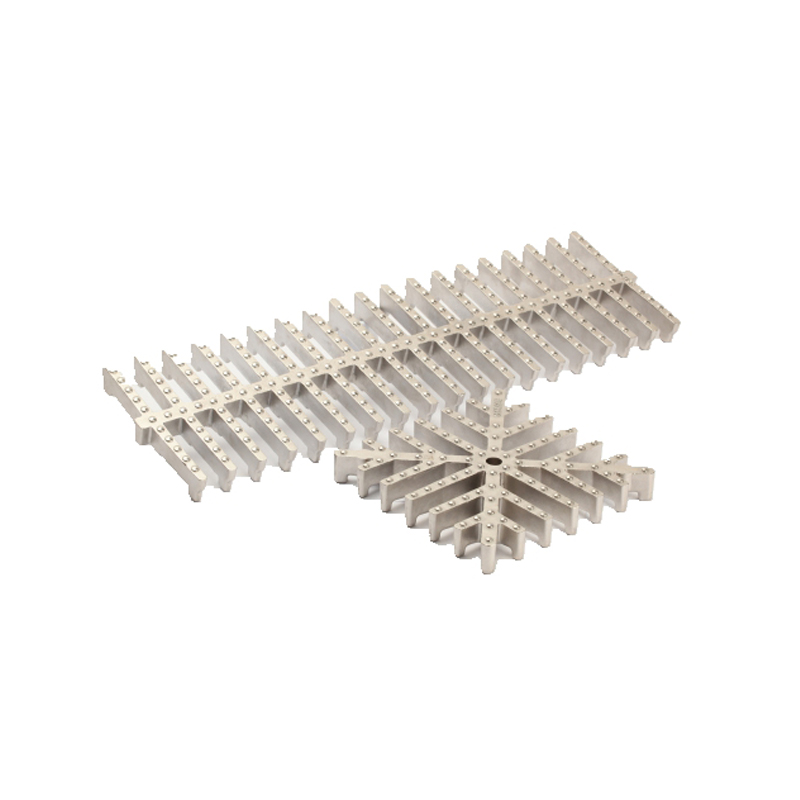

Upscale hotel precision casting stainless steel floor drain

| Product | Name | Material | Application | Casting tolerance |

|

Upscale hotel precision casting stainless steel floor drain | AISI 316 | Upscale hotel | ISO 8062 CT6 |

A filter should always be fixed to the floor drain to prevent injuries, foreign objects, or harmful pests from entering the facility. However, if the filter is not smooth enough, hair and other objects will still get stuck inside and block the sewer.

Floor drain is a type of floor drain mainly used as an indirect waste receiver. It is usually deeper than a standard floor drain, and can have a complete or partial grille, or no grille as needed to accommodate indirect wastewater pipes. It usually has a dome filter at the bottom to prevent splashing back. The valve body material can be epoxy coating or enameled cast iron, stainless steel or PVC. Floor sinks are found in commercial kitchens and some hospital applications.

Drawing→ Mold → Wax injection→ wax tree assembling→ Shell moulding→ Dewax-buring→ pouring→ Shell removing→ Cuttiing-Griding→ Machining → Deburring → Surface Finishing → Assembly → Quality Inspection→ Packing